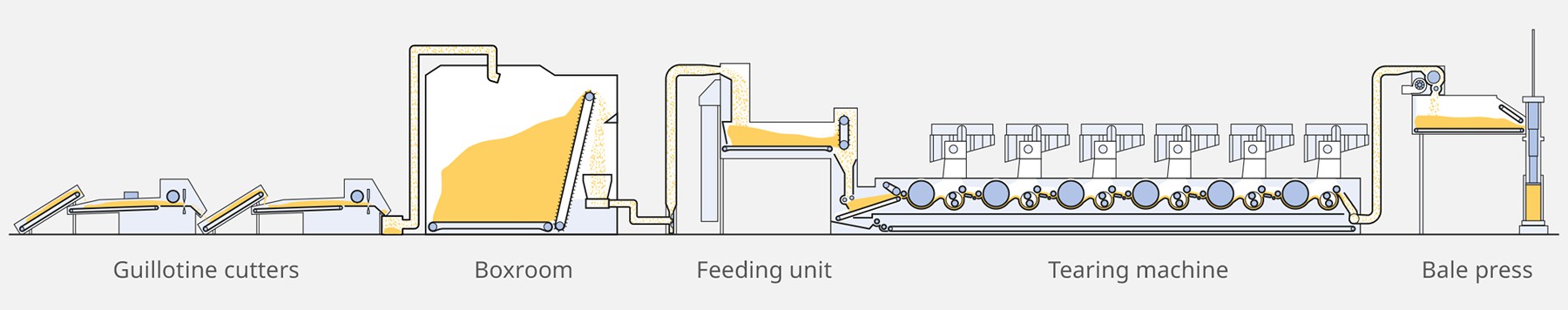

Structure of a tearing line

The first step is the cutting of the textile hard waste. The starting material is cut into small pieces of fabric by two guillotine cutters. In a box room, the material is homogenized and stored in batches. The material is then evenly fed into the tearing machine via the feeding unit. The material is disintegrated into fiber tufts via six cylinders that are equipped with needle bars. The fiber tufts are finally sucked off after the tearing machine and pressed in a bale press.

Cutting

Two guillotine cutters cut the textile hard waste to the required size for the tearing machine. The first guillotine cutter is equipped with a metal detector. The second guillotine cutter stands 90° offset to the first one. This makes sure uniform pieces of fabric are cut.