The shortest way for you rotor-spun yarn

The higher the content of comber noils and short fibers, the greater the benefits of IDF direct spinning. The special drafting system geometry and the respective settings make for smaller roll gaps. This ensures that the fibers are guided and clamped reliably in order to control floating fibers.

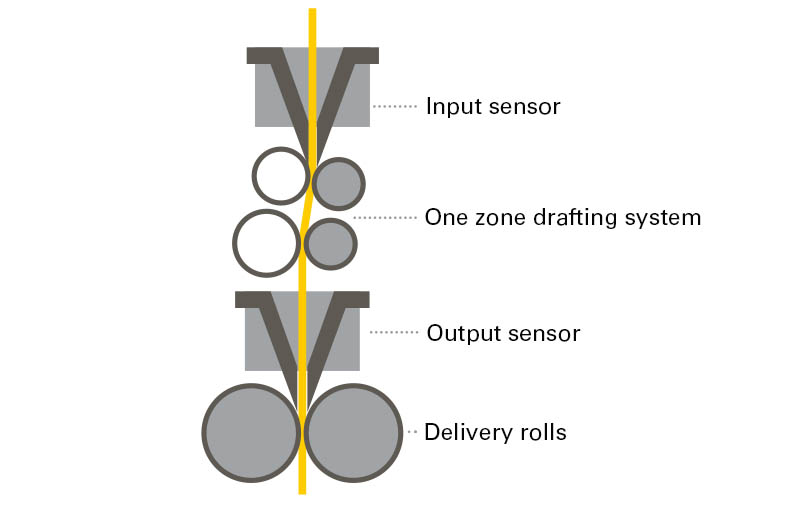

With only one drafting system zone, minimal drafts are achieved. The risk of incorrect drafts and the resultant variation in yarn count are thus minimized.

Perfect harmonization: Perfect combination

Truetzschler cards give you the advantage. They produce a thinner and more stable web which is perfectly suited for being drawn directly to the desired sliver count by the IDF 2, and all at the lowest drafts. Particularly when it comes to recycling applications the short fiber content is high and the fiber lengths are low. Minimum drafts to prevent floating fibers and package formation and to produce an optimum yarn are only achieved with the IDF 2 with one drafting zone and the Truetzschler web doffer, which produces a thin but stable card web.

More effective with one drafting system zone

When the yarn data is analysed, it becomes clear that the splitting of the draft into break draft and main draft generally has a negative effect on the quality of the yarn or, in the best case, it delivers the same results but with much more effort for setting. Truetzschler is therefore backing a single drafting system zone which can clamp short fibers gently and effectively thanks to the smaller gaps between the rolls.

Further developments IDF 2

The IDF too is subject to a process of continuous improvement. Most recently, for instance, a retaining catch for the cover was integrated to make handling when piecing up much simpler. The self-adjusting lap monitoring of the top rolls from the draw frames was also transferred to the IDF.

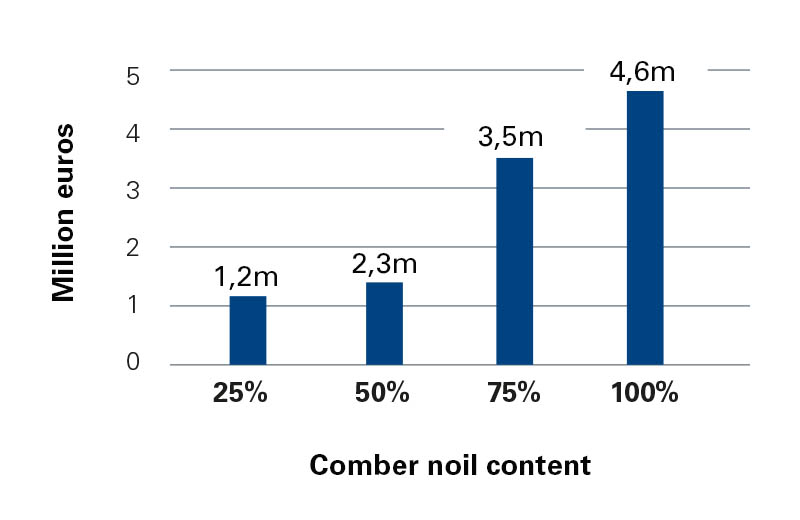

Immense annual cost savings thanks to inclusion of noils

The price of raw materials is one of the largest cost factors for a spinning mill. So why not reduce costs and allow the addition of noils depending on the application? The resulting annual cost savings with just a 25 % noil content stand at more than € 1m. (Costs for cotton € 1.5/kg / noil € 0.95 /kg, production rate 21t per day)