Permanent savings only with the IDF 2

Particularly in the spinning mill with its numerous machines, reduced process stages quickly multiply to great economic advantages.

Multidimensional advantages from fewer process steps:

- Reduction in investments

- Less tied up capital in the process

- Reduction of workload

- Minimization of errors

- Space savings

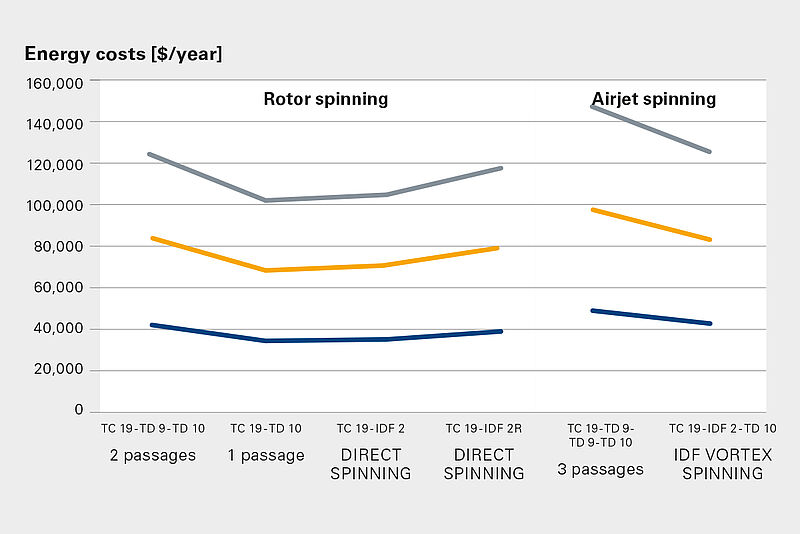

IDF 2 reduces the investment and operating costs

A process reduction always generates savings. In addition to the purchase costs, the operating costs as well as the service and maintenance costs are also eliminated.

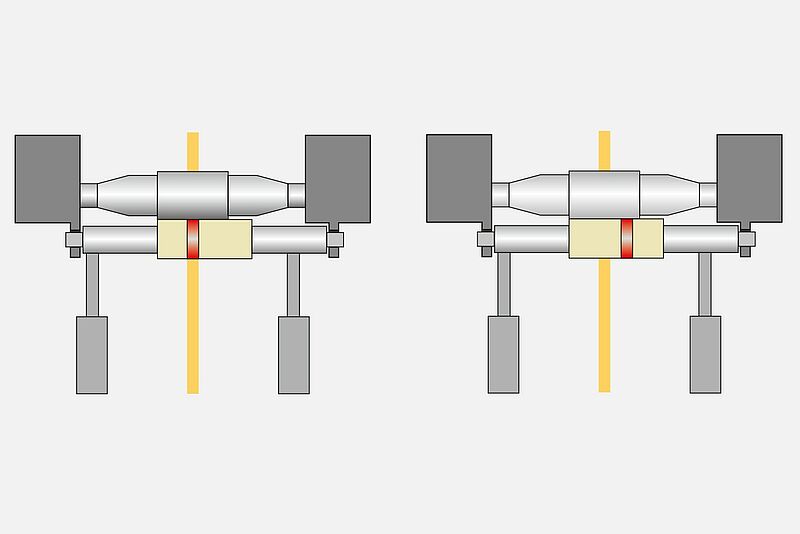

The operating costs are not only reduced by a lower power consumption: 48 % less can transports and piecings at the spinning machine when using rectangular cans. Less piecings also mean a reduction of yarn imperfections.

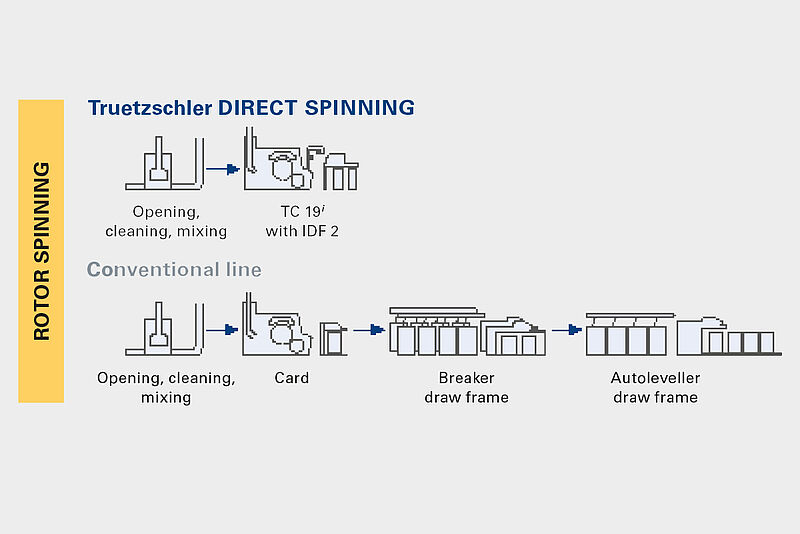

Leading edge for rotor yarns

The Trützschler spinning preparation gives you the unique opportunity to process 100 % waste into a respectable yarn. Take advantage of these benefits, for instance by using a separate small line for processing spinning waste such as noils from a ring spinning installation.

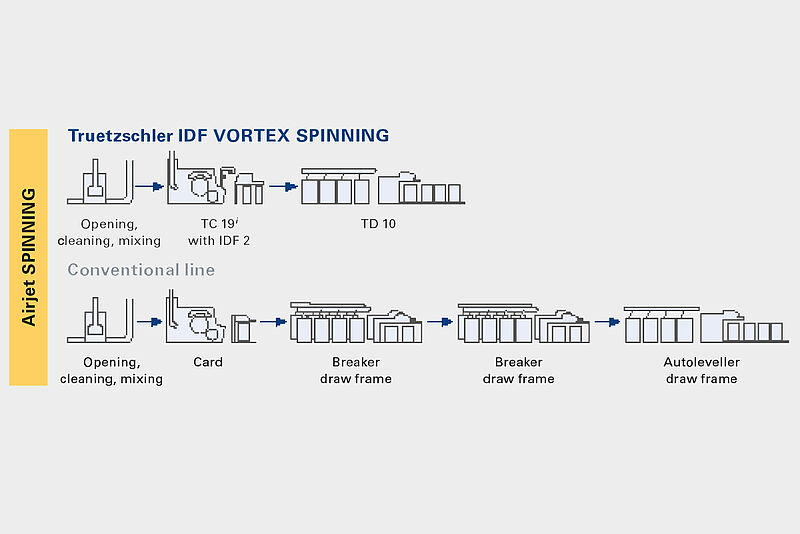

Leading edge for airjet yarns

The Trützschler spinning preparation gives you the option to drastically shorten the preparation process on IDF 2 and autoleveller draw frame. But even when using the classic process with three passages you can increase productivity thanks to the efficient TWIN BUT INDEPENDENT concept.

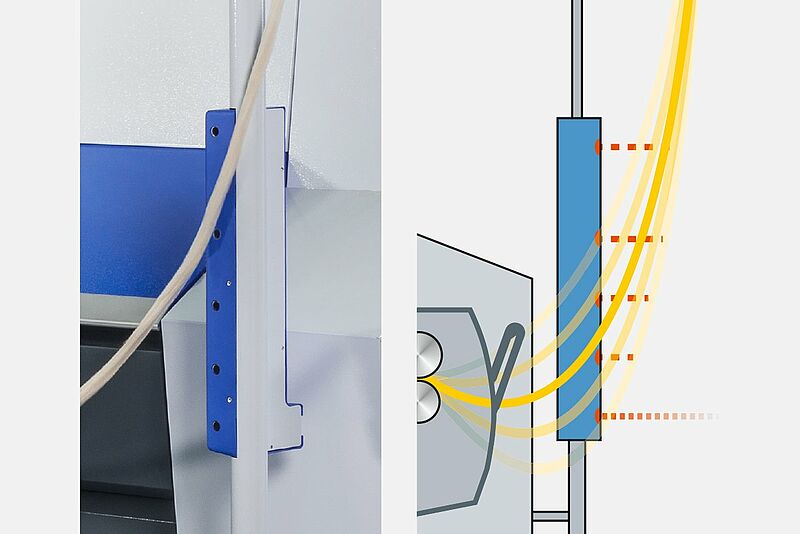

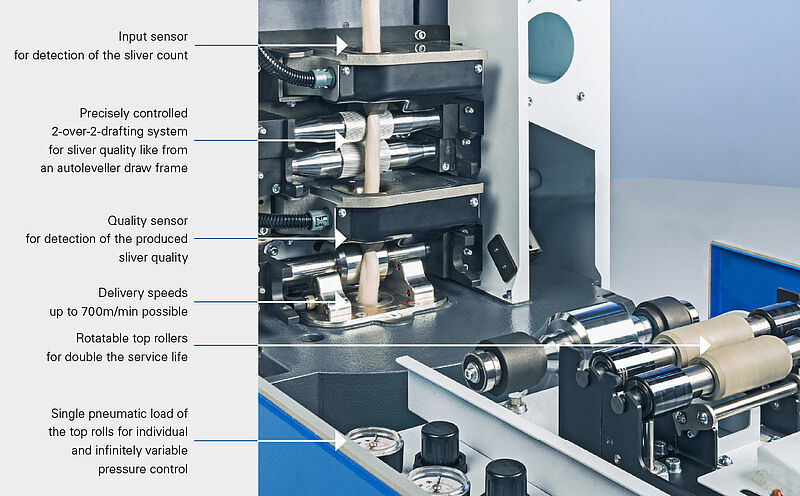

Draw frame technology of an autoleveller draw frame – the IDF 2

Levelling quality without compromises

The close spatial proximity of the measuring point and drafting system and the low mass inertia allow a reliable levelling of the draft. To ensure that every metre in the can has the desired quality, the sliver is permanently checked by the second sensor positioned immediately behind the drafting system.